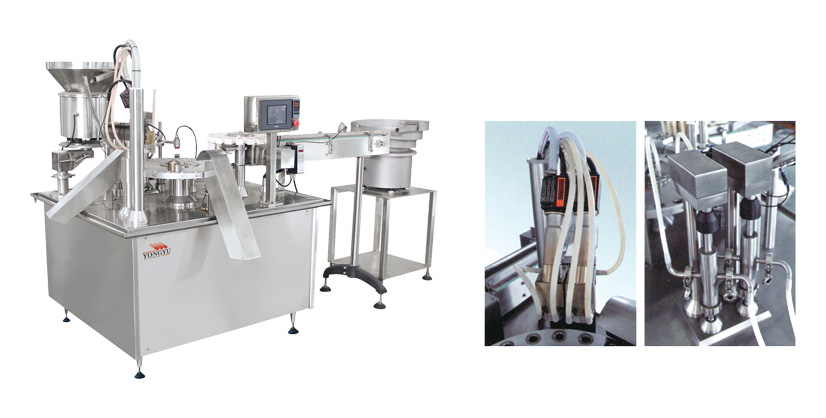

USAGE & INTRODUCTION:

The unit meets the requirements of "cGMP", and is suitable for filling and heat sealing of new type flexible plastic bottles. It is designed with reference to similar foreign models. This machine is the preferred equipment for oral liquid filling production in China, through a series of special processes, such as automatic bottle-feeding, bottom filling, automatic capping, hot-melt bottom sealing, mechanical hand delivering bottles and so on.

CHARACTERISTIC:

The whole machine adopts PLC control, man-machine interface operation, automatic and manual switching control. It has the functions of empty bottle leak detection, bottle filling stop, capless bottle and bottle leak elimination, variable frequency stepless speed regulation, automatic counting and so on. The whole machine has compact structure and high degree of automation. The flexible plastic bottles equipped with this machine are manufactured in clean areas, which can reduce the washing, drying and sterilization processes, save space, and have the advantages of not breaking in bottling and transportation.

MAIN TECHNICAL PARAMETERS:

Applicable specifications: 10ml, 15ml, 20ml (special, easy to break plastic bottle)

Production capacity: 40 bottles / min, 80 bottles / min

Metering mode: full metal rotary piston pump

Measurement accuracy: in line with national Pharmacopoeia

Sealing Method: Automatic base melt closure

Compressed air consumption: 1.2m3/min (pressure 1MPa); 1m3/min (pressure 0.8MPa)

Total power: 10kW

Power supply: 380V 50Hz three-phase five-wire system

Dimensions: 3000 × 1700 × 2400 (mm)